Industrial Generator Sizing: Key Considerations and Best Practices

Print

PrintWhat is the perfect generator size for your mission-critical needs?

Learn how to size backup generators for mission-critical sites like hospitals, data centers, and plants - ensuring reliability, performance, and compliance.

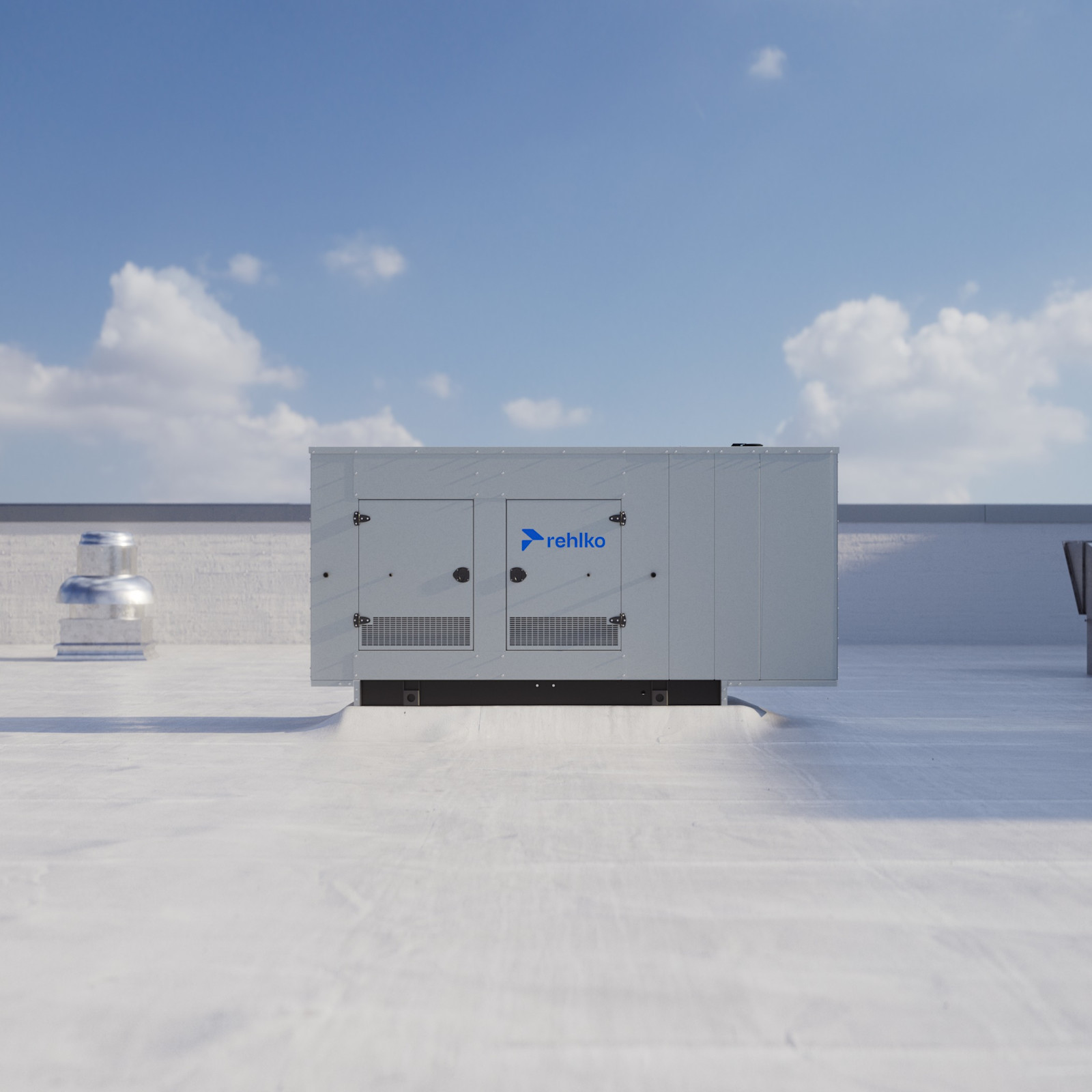

Standby generators play a crucial role in mission-critical applications, including data centers, healthcare facilities, and water treatment plants.

In the event of a grid failure, these proven pieces of equipment come online in seconds, providing essential backup power for continuity of operations. Indeed, generators are the unsung heroes of the modern world – and are relied upon to keep your business running.

But how do you ensure that every generator is properly sized for the task at hand? This process involves multiple considerations, with factors such as reliability, capacity, performance, and codes and standards. Most standby generators are permanently installed onsite, so it is essential to get it right the first time.

The value of sizing software

To make this process quicker, easier and more accurate, it is advisable to use sizing and specification software to ensure the proper selection is made.

Rehlko Power Solutions Center software, available online at https://www.pscweb.rehlko.com/, can be used to select the right generator for the site's specific conditions. It is a flexible and adaptable tool. For example, you can consider future electrical loads that may be planned or simulate how building expansions might require an additional generator and how that load scheme will connect with the existing infrastructure.

Inputting the right information

Let's examine the use of the sizing software in more detail. It allows designers to run endless simulations and scenarios involving many complex and dynamic calculations, all made within seconds based on the varied inputs from the designer.

Sizing program inputs may include utility load reports, site-specific conditions, electrical parameters, emissions, alternator temperature rise, regional codes, transient performance, and fuel type and capacity. Electrical load types can also be entered to create a load calculation for estimating the size of a generator. These may include lighting, motors, and HVAC.

There is also the option to design load profiles by categorizing loads (such as life safety, critical, etc.) and considering whether they are continuous or intermittent. Motor loads and timing of load schemes also play a part in the equation.

Installation factors, such as space and logistics, sound considerations, room sizing, and regional codes and standards – which in places like the US may cover seismic standards – will also provide essential parameters for selection.

Generator selections made clear

Once the process is underway, the sizing software will recommend a generator based on the inputs and display product suggestions to review the performance differences.

The sizing software should consider both the engine and alternator characteristics of a generator, as the engine is the mechanical source of power that is converted to electrical power by the alternator. The engine frequency dip is a good indicator of the generator's ability to pick up loads as well as the alternator’s voltage dip.

The construction and size of the alternator and its exciter, its motor-starting capacity, as well as the voltage regulator volts per hertz setting can impact the generator's ability to accept a load. Rehlko offers multiple engine and alternator combinations to meet the various site requirements.

The benefits of an oversized alternator

Selecting a generator with an oversized alternator (one that has a lower temperature rise value than the nameplate rating) may provide extra durability or an increased safety factor. The alternator temperature rise is a value determined through National Electrical Manufacturers Association testing. The industry standard for standby generators is typically 130°C (standby duty). The alternator temperature rise rating correlates to the number of run hours per year. Standby generators are a secondary source of power; therefore, with a reliable utility, the annual usage is typically low.

As the alternator temperature rise rating goes lower, the hours of life increase with the same load applied. The temperature rise is measured when full output power is removed from an alternator. For example, a 3000 kW generator with an 80°C (continuous duty) temperature rise means the alternator operates under load at a lower temperature than a typical standby alternator with a 130°C temperature rise.

Rehlko typically offers at least two levels of oversized alternators (105°C and 80°C) per generator as standard product offerings, which are displayed in the Power Solutions Center. However, it can also provide custom alternator solutions, factory-ordered through Rehlko distributor partners.

Understanding power quality factors

Beyond alternator considerations, the sizing process must also account for power quality factors that can affect system performance. Evaluating harmonic distortion and its impact on loads helps ensure that downstream equipment is not damaged.

A practical solution is to use in-line filters at the site to reduce total harmonic distortion, which will typically cost less than a larger generator recommended due to the high harmonics introduced by various load types. Rehlko Power Solutions Center software enables designers to adjust parameters in the Advanced Settings to match the load specifications provided on the equipment's specification sheet.

Keeping your business running

Ultimately, the sizing software is a valuable tool in ensuring that data centers, healthcare facilities, water treatment plants, or any other emergency generator application will allow for a selection of the most suitable generator.

Getting this decision right upfront can lead to reliable operations over the long term, ensuring mission-critical applications perform as needed. With Rehlko's sizing software, first-class portfolio of generators and high-quality aftermarket support, we can help keep your business running.

Power sizing program.

Power sizing program.

Need the perfect power solution? Our user-friendly sizing program, Power Solutions Center, puts the power of precision at your fingertips. This web-based tool is the ultimate solution for quickly and accurately specifying and sizing your power system. No matter where you are.

EXCLUSIVE FEATURES

Drag-and-drop load management

Automated one-line diagrams and step reports

Optimized generator set results

Comprehensive summaries, reports, and technical documents

Fast, easy estimates and information