Revolutionizing Mission-Critical Power

Print

PrintRehlko and KVH

How a partnership between Rehlko and a major hospital in the United States is paving the way for hydrogen fuel cell system solutions.

Mission-critical facilities such as hospitals, airports, data centers and water treatment plants increasingly seek to combine resiliency and sustainability when deploying on-site backup power.

First and foremost, these places need dependable power to underpin 24/7 operations, and every effort must be made to ensure the continuity of supply. But many end-users are increasingly aware of their environmental responsibilities and want to achieve this resiliency by using power generation technologies that are more efficient and have lower emissions at the point of use.

These considerations require imaginative thinking around mission-critical strategies - often achieved by combining tried and trusted equipment such as generators with more novel systems and approaches.

Fuel cell deployment

The pursuit of resiliency and sustainability has been brought sharply into focus at Klickitat Valley Health, a major healthcare facility in Washington state, US. Here, a highly innovative 100 kW hydrogen fuel cell system has been deployed for grid-following and emergency backup applications while exporting excess power to the grid through a net metering program.

The power of partnership

So how did the fuel cell system come about? From the outset, Klickitat Valley Health collaborated with Rehlko and Toyota Motor North America to develop and install a hydrogen-powered fuel cell system. This collaborative effort began with an intense period of research and development, proving and integrating a broad array of technologies on the commercialization of the Rehlko fuel cell system.

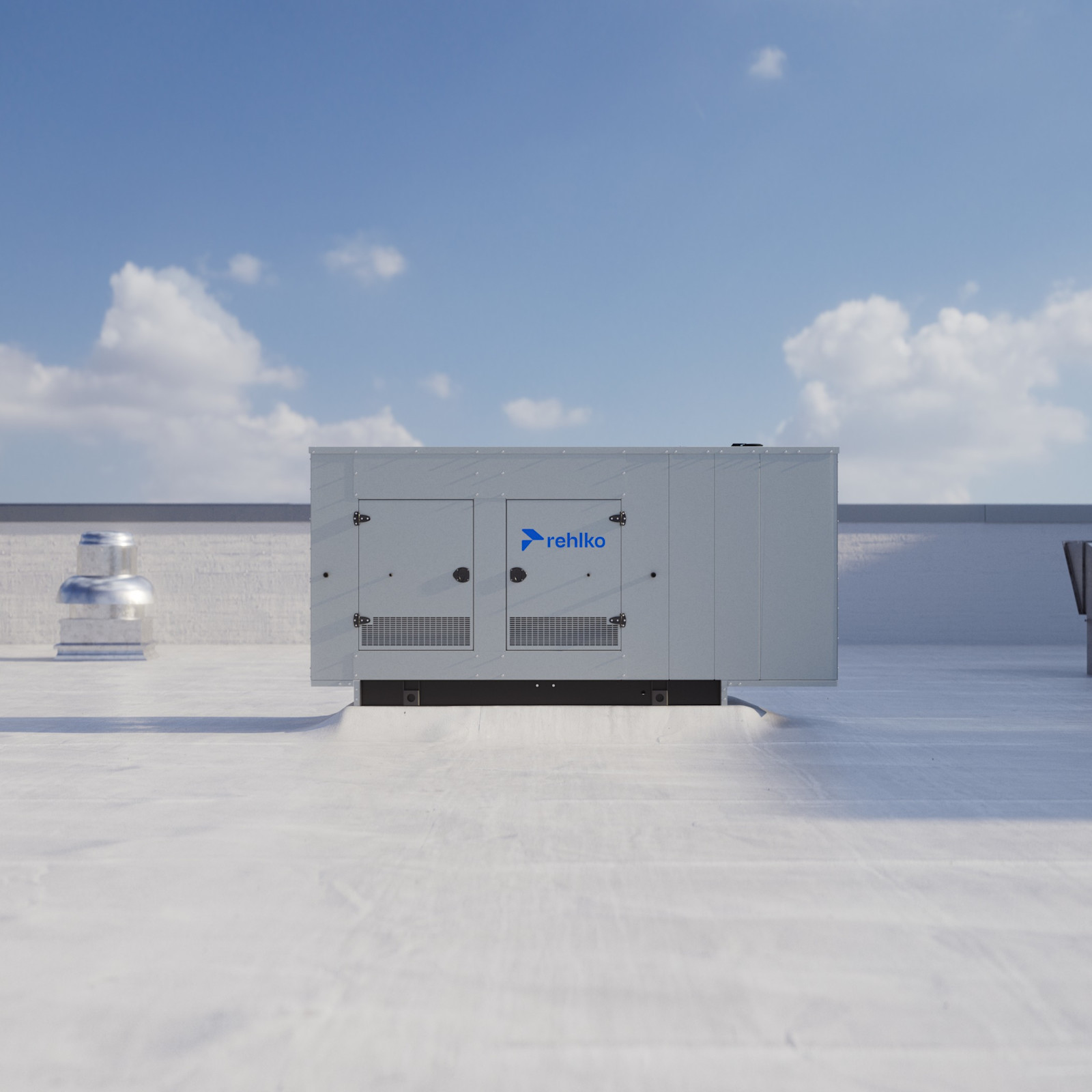

The hospital wanted a modular and scalable container-based design with fully integrated controls. Rehlko took one-source responsibility for the generating system and accessories, including electrical architecture, exhaust, cooling and fuel inlet system. Other technical and performance characteristics include a compact, durable steel housing featuring lockable access doors and a textured paint finish for corrosion and abrasion protection.

Built to last

The Rehlko fuel cell also needed to be designed for easy operation, with an intuitive controller for one-source system integration and communication. Features developed by Rehlko included:

An externally mounted emergency stop switch.

Electronic trip main line circuit breaker.

Remote start/stop.

The unit also had to meet the most stringent safety accreditations, such as the National Fire Protection Association’s NFPA110 standard for emergency and standby power systems. It was also designed to operate in a broad range of temperatures, from -30 to 45C, and offered a low-maintenance 20,000- hour design life.

Identifying other applications

Klickitat Valley Health will use the Rehlko fuel cell system for emergency backup, peak shaving, and demand response. Still, a broad range of end-users could use this system in any application requiring sustainable and resilient prime or backup power, providing on-site access to a hydrogen fuel supply. It could, for instance, be deployed in maritime environments like ports to provide dock-side shore power, reducing emissions from ships idling at berth. Also, with the trend towards vehicle electrification gathering pace, the Rehlko fuel cell system could be used to recharge electric vehicles.

There are plans to scale the system from 100 kW to 500 kW, then 1MW. Rehlko is currently discussing those sorts of power requirements with several partners and is also working with key supply partners, such as Polymer Electrolyte Membrane (PEM) technology developers, to refine and improve system integration.

Global ambitions

The Klickitat Valley Health project represents an exciting and innovative first example of the commercialization of Rehlko’s fuel cell solution.

But ultimately, such systems could be factory-built and production-readied at Rehlko facilities in the US, Europe and elsewhere. This strategy would provide end-users with product consistency for resilient and sustainable fuel cell system power worldwide.