Case Study: Emergency Power for Water Treatment Facility

Print

PrintCentral Arkansas Water | Little Rock, Arkansas

At a Glance

CUSTOMER

Central Arkansas Water

LOCATION

Little Rock, Arkansas

CHALLENGE

Provide standby emergency power for Ozark Point water treatment plant equipment

SOLUTIONS

KD1250-A generator

Rehlko APM603 controller

Rehlko Sound Level 2 enclosure

Rehlko integral sub-base fueltank with 5,808-gallon capacity

Rehlko integral catwalk and interior lighting

Rehlko PD-Series paralleling switchgear

PRIMARY CHOICE FACTORS

Confidence in Rehlko (formerly Kohler Energy) product reliability and strong relationship with Rehlko authorized distributor.

Note: Kohler Energy is now Rehlko. The products shown were installed under the KOHLER brand.

Background

There are several critical steps in the water treatment process, including those for potable water and wastewater. The entire process starts with coagulation and flocculation, and then moves to sedimentation, filtration, and disinfection. The goal is to separate and remove solids and eliminate bacteria such that they do not pose environmental issues or drinking water hazards.

The sedimentation step uses chemicals, charge attraction, and gravity to settle out solids and harmful particles. Filtration is the backbone of treatment. This step includes forcing water through various grades of either anthracite, coal or sand, and gravel which serve as filter mediums.

Flocculation basin deck at Ozark Plant with electric mixer motor

Sedimentation basin at Ozark Point with sludge collection electric motor

This seemingly simple approach is efficient and effective in terms of removing unwanted particulate matter. Ultimately, this aggregate medium must be back flushed to retain its filtration effectiveness. Once water passes through the remaining filtration step, it is put into the distribution system under constant pressure to prevent intrusion of contaminants from the exterior of the distribution system.

The Ozark Point water treatment plant uses several high-horsepower motors for the filter backwash process and water distribution system pressurization. When Central Arkansas Water (CAW) wanted to expand its water treatment facility and ensure constant power for its new high service pumps, new backwash blowers, and other existing plant loads, it knew it could rely on Rehlko standby power solutions and the expertise of the Rehlko authorized distributor, which specializes in water and wastewater treatment facility power needs.

The collaboration between Rehlko, the Rehlko authorized distributor, and Max Foote allows CAW to maintain full plant operation regardless of external power issues.

Challenge

The project posed several challenges, not least among them, the location of the site. Adjacent to an historic area, the streets were narrow and had several tight curves, posing difficulties for the cranes, semitrucks and other heavy equipment required for the delivery, offloading, and installation of the equipment.

Complicating the solution was the need to power the existing electrical service with 2400 VAC, three-phase. The design was based on providing 2400 VAC switchgear to match the existing electrical service. Subsequently, a decision was made to provide a 480 VAC, three-phase generator that could accommodate the integration of a rental generator when the permanent generator was down for service or repairs.

To facilitate this addition, a step-up transformer was used to step up the 480 VAC emergency generator set voltage to the 2400 VAC utility service voltage connected to the 2400 VAC paralleling switchgear. The new 2400 VAC paralleling switchgear would service all existing water treatment plant loads as well as a new 200-hp high-service pump. In addition to the new 200-hp pump, other high-service pumps were added including 125-hp, 300-hp, and 400-hp units. By design, the additional motors would be shed during emergency operation, making it possible to optimize the generator set capacity, and yet keep the plant operational given a utility outage.

Solution

The emergency standby solution for the water treatment plant expansion includes a Rehlko KD1250-A generator set, featuring a Rehlko brushless, permanent-magnet pilot exciter alternator for excellent voltage response and short circuit capability. The generator features the Rehlko KD Series™ engine, specifically engineered for generator applications. The engine is designed to deliver high power density and optimized fuel efficiency across a wide range of output nodes. The result is higher performance at reduced operating costs. It runs smoothly and quietly, creating very little vibration, even under extreme operating conditions. On-board diagnostics provide operator insight for easier maintenance and long-term performance.

An aluminum sound level 2 enclosure with Power Armor™ automotive-grade finish provides advanced corrosion and abrasion protection as well as enhanced edge coverage and color retention. An internal silencer provides quiet operation, maximum component life, and increased operator safety. A cold-weather package consisting of a generator heater, block heater, and battery charger ensure operation in inclement conditions.

The generator set also features a Rehlko-manufactured, UL 142 integral subbase, fuel tank with a 5,808-gallon capacity. It offers continuous operation until grid power is restored or refueling needed. The tank features Power Armor Plus textured epoxy-based rubberized coating which prevents corrosion. It is also UV resistant. Both the inner and outer tanks have emergency relief vents. The subbase tank also features an environmentally friendly secondary containment tank surrounding the primary tank. Integral stairs and catwalk, multiple doors on each side, and interior lighting provide easy access for service and maintenance.

The diesel-fueled generator set also features a Rehlko APM603 controller for one-source system integration and remote communication. The APM603 generator set controller provides advanced control, system monitoring, and system diagnostics for a single generator set or paralleling of multiple generator sets. The APM603 interfaces the generator set to other power system equipment and network management systems using standard industry network communications. It uses a patented digital voltage regulator and unique software logic to manage alternator thermal overload protection. It also serves as an overcurrent protective relay. The APM603 controller meets NFPA 110, Level 1.

A seven-inch color TFT touch screen display provides easy access to data, including visibility to warnings and faults with text description and code display. The SnapShot feature automatically captures 15 seconds of key data around each warning or shutdown.

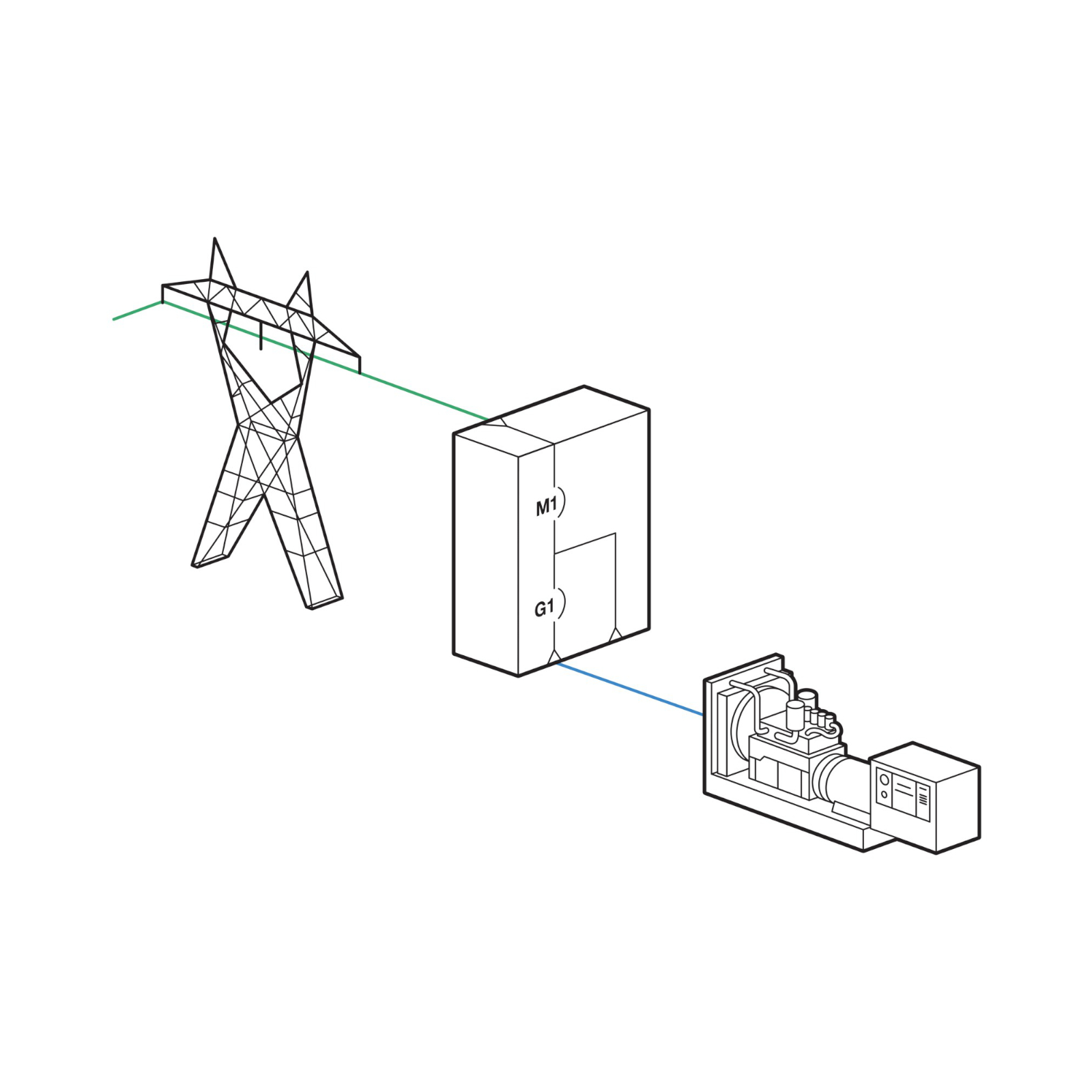

To facilitate the integration of generator and controls, utility services, and other distribution equipment, the solution includes Rehlko PD-Series paralleling switchgear.

Rehlko PD-Series paralleling switchgear provides an industry-leading platform for command and control of multiple power sources. Designed to be integrated with Rehlko generator sets or combined with other major brands of generation equipment, the PD-Series paralleling switchgear delivers outstanding reliability along with the most intuitive user interface in the industry. The PD-Series paralleling switchgear is extremely flexible. Incorporating patented mode configuration technology, the owner may select from a variety of operational parameters and sequences without any additional cost. In addition to the digital control interface, the PD-Series may be constructed with any of the more traditional metering, control, and other component requirements based on an engineer’s or owner’s preferences.

The solution for Central Arkansas Water includes:

A Rehlko KD Series generator, PD-Series paralleling switchgear, HMI-equipped control panel, and the APM603 controller - delivering advanced monitoring, seamless integration, and reliable power management.

KD1250 Diesel Generator

APM603 Controller

Single Utility Switchgear

Results

The integrated emergency standby power solution for Central Arkansas Water (CAW) has been commissioned and is performing exceptionally well. The staff at CAW knows it can count on Rehlko reliability. The custom work was designed by Brown Engineers and performed by Max Foote Construction and Koontz Electric to properly integrate the Rehlko solution. This allowed allowed CAW to meet a precise need now, as well as into the future, as further expansion plans are being developed. According to CAW Operations Manager, Doug Graham, “The collaboration between Rehlko, the Rehlko authorized distributor, and Max Foote allows CAW to maintain full plant operation regardless of external power issues.”

Case Study

Education

Learn why this university in Kansas trusts in a Rehlko Power System.

Case Study

Education

Rehlko generators helped North Iowa Community College cut utility costs and boost energy independence with a solar-integrated microgrid system.

Case Study

Water Utility - Pump Station

Learn how one town upgraded quiet, reliable generators for water infrastructure. Discover solutions that simplify purchasing and ensure resilience.