At a Glance

CUSTOMER

Fort Hays State University

LOCATION

Fort Hays, Kansas

CHALLENGE

Provide the most modern peak shaving (load curtailment) system while paralleling the system with the local utility, existing standby, and wind turbines.

SOLUTIONS

Two Rehlko KD SeriesTM generator sets

Rehlko APM603 controllers

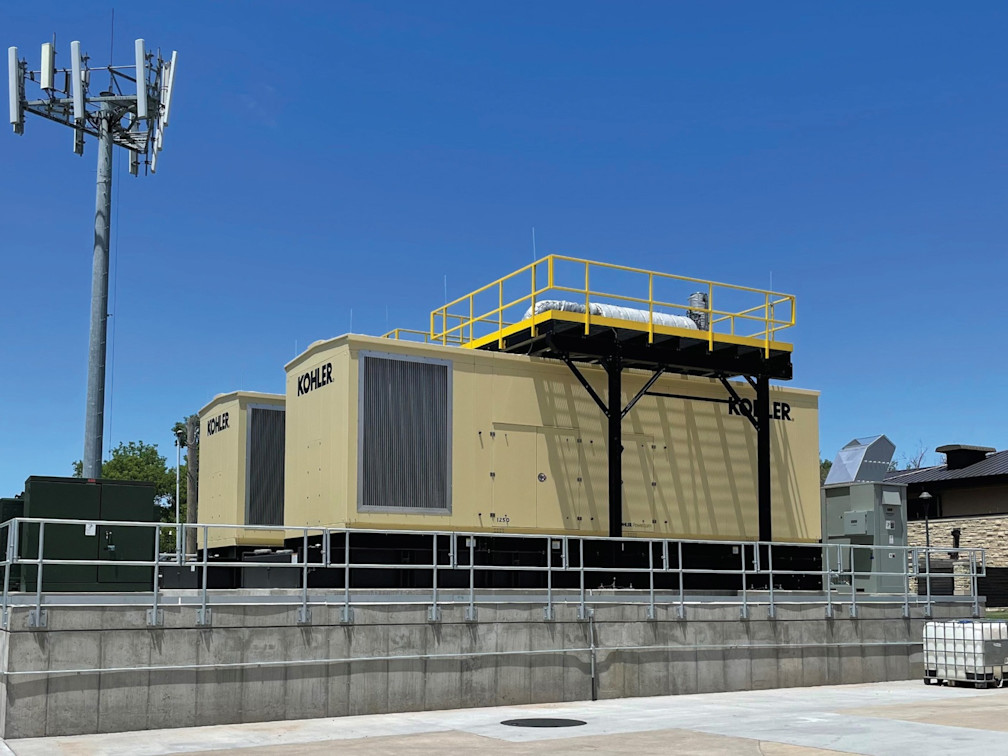

Rehlko Sound Level 2 enclosure

Two Rehlko integral subbase 48-hour state fuel tanks with 2960-gallon capacity

Rehlko PD-Series utility paralleling switchgear

PRIMARY CHOICE FACTORS

Rehlko's advanced KD generator sets and local distributor’s experience paralleling multiple energy sources in association with Rehlko’s Power Solutions Team.

Note: Kohler Energy is now Rehlko. The products shown were installed under the KOHLER brand.

Background

Founded in 1902, Fort Hays State University (FHSU) is a public institution located in Hays, Kansas. The university was originally located on the grounds of Fort Hays, a frontier military outpost. The 200-acre campus includes over 40 limestone-faced buildings reminiscent of its founding as well as other facilities. With an enrollment of 15,100 students, the university boasts 31 academic departments and offers more than 60 academic majors for undergraduates and 20 for graduate students.

The university’s motto is: Forward thinking. World ready. The motto reflects the university’s embrace of sustainability, wherein it supports initiatives that parallel those of the Association for the Advancement of Sustainability in Higher Education (AASHE). The association has adopted the widely known and utilized sustainability framework of the UN 17 Sustainable Development Goals. It provides the scorecard and metrics system (STARS) that allows FHSU to benchmark itself against its peer and aspirational peer institutions.

A designated committee at the university is responsible for initiatives designed to advocate sustainable development without compromising the ability of future generations to meet their own needs.

In alignment with its sustainability vision, the university is engaging in infrastructure modernization. It already converted its HVAC equipment to variable-speed technology and optimized its natural gas use and boiler operation. The university also knew it was facing the replacement of its current peak shaving system because it was nearing the end of its life cycle.

Challenge

Though the university would likely retain its 1500-kW generator unit, it was interested in how newer generator system technologies, like Tier 4 Final, and improved controllers and switchgear, could contribute to reduced energy consumption, maintenance costs, and decarbonization. The job would also require the switchgear to parallel a variety of energy sources, including the utility, the remaining generator, and its two, 2 MW wind turbines.

Solution

To help understand the options, FHSU’s director of energy, Keith Dreher, reached out to a local distributor who proposed a comprehensive solution. The heart of it included a set of Rehlko generators. Their innovative design precludes the need for expensive aftertreatment equipment like a diesel oxidation catalyst (DOC) device and a diesel particulate filter (DPF).

Generators used for peak shaving face a different set of emission hurdles than standby generators. Every three years they must go through stack testing to ensure their emissions comply with the Environmental Protection Agency (EPA). Clean Air Act (CAA). More specifically, stack tests evaluate the effectiveness of emissions capture equipment (the aftertreatment system) typical on this type of generator—the DOC and the DPF.

The DOC is the first device in the after treatment system. A DOC is a separate unit from the DPF but works in tandem. It is designed to convert carbon monoxide (CO) and hydrocarbons into carbon dioxide (CO2) and water. It is a flow-through filter that contains precious metals to start the oxidation of hydrocarbons, carbon monoxide, and unburned fuel and oil. Both the DOC and the DPF are honeycomb ceramic filters.

The DPF is also an exhaust aftertreatment device that reduces harmful emissions. The DPF is a wall flow filter that traps any remaining soot that the DOC couldn’t oxidize. It filters out particulates like soot, ash, and unburned hydrocarbons. The soot remains in the DPF until it is regenerated either passively or actively.

The DOC and DPF components on a generator add significant cost to the unit, increasing cost of ownership. Moreover, regular stack testing adds additional financial burden.

KD diesel engines on the generators incorporate in-cylinder emissions control technology. The cylinder heads, combustion chamber, and high-pressure common rail fuel injection system are optimized to enhance power density, decrease noise, and control emissions.

To meet Tier 4 Final requirements relative to reducing nitrogen oxide (NOx) emissions, Rehlko incorporated an exhaust aftertreatment system (EATS) for its KD Series™ generators. It uses selective catalytic reduction (SCR) technology wherein Diesel Emission Fluid (DEF) is part of the process. This fluid contributes to the further break down of nitrogen oxides that pass through to the SCR filter. Typically, the SCR filter doesn’t need maintenance except in rare events where a component related to the DEF fluid fails.

The Rehlko EATS system includes an anticorrosive stainless steel tank with mounted pump controls and service touchpoints that are centrally located for ease of service and maintenance. The DEF system is DC-powered by a dedicated power supply. It does not require compressed air and is purged back into the DEF tank when not in use. Each generator features one SCR.

The generators also feature Rehlko APM603 controllers for one-source system integration and remote communication. The APM603 controller provides advanced control, system monitoring, and system diagnostics for a single generator set or paralleling of multiple generator sets. The APM603 interfaces the generator set to other power system equipment and network management systems using standard industry network communications. It uses a patented digital voltage regulator and unique software logic to manage alternator thermal overload protection. It also serves as an overcurrent protective relay. The APM603 controller meets NFPA 110, Level 1. A seven-inch color TFT touchscreen display provides easy access to data, including visibility to warnings and faults with text description and code display. The SnapShot feature automatically captures 15 seconds of key data around each warning or shutdown.

The enclosed generators feature Sound Level 2 enclosures as part of the standard package making it ideal for a school setting like FHSU. The Rehlko manufactured integral subbase 48-hour (2960 gallon) state fuel tank for each generator is also standard. The tank features Power Armor™ textured epoxy-based rubberized coating which prevents corrosion. It is also UV- resistant.

Both the inner and outer tanks have emergency relief vents. The subbase tank also features an environmentally friendly secondary containment tank surrounding the primary tank. The FHSU solution also includes a custom-built mezzanine system which was provided by Rehlko. It allows easy access to the SCR for inspection and service.

Two diesel generators installed on the Fort Hays State University campus

PD-Series switchgear control panel with HMI screen

Switchgear Power Solutions

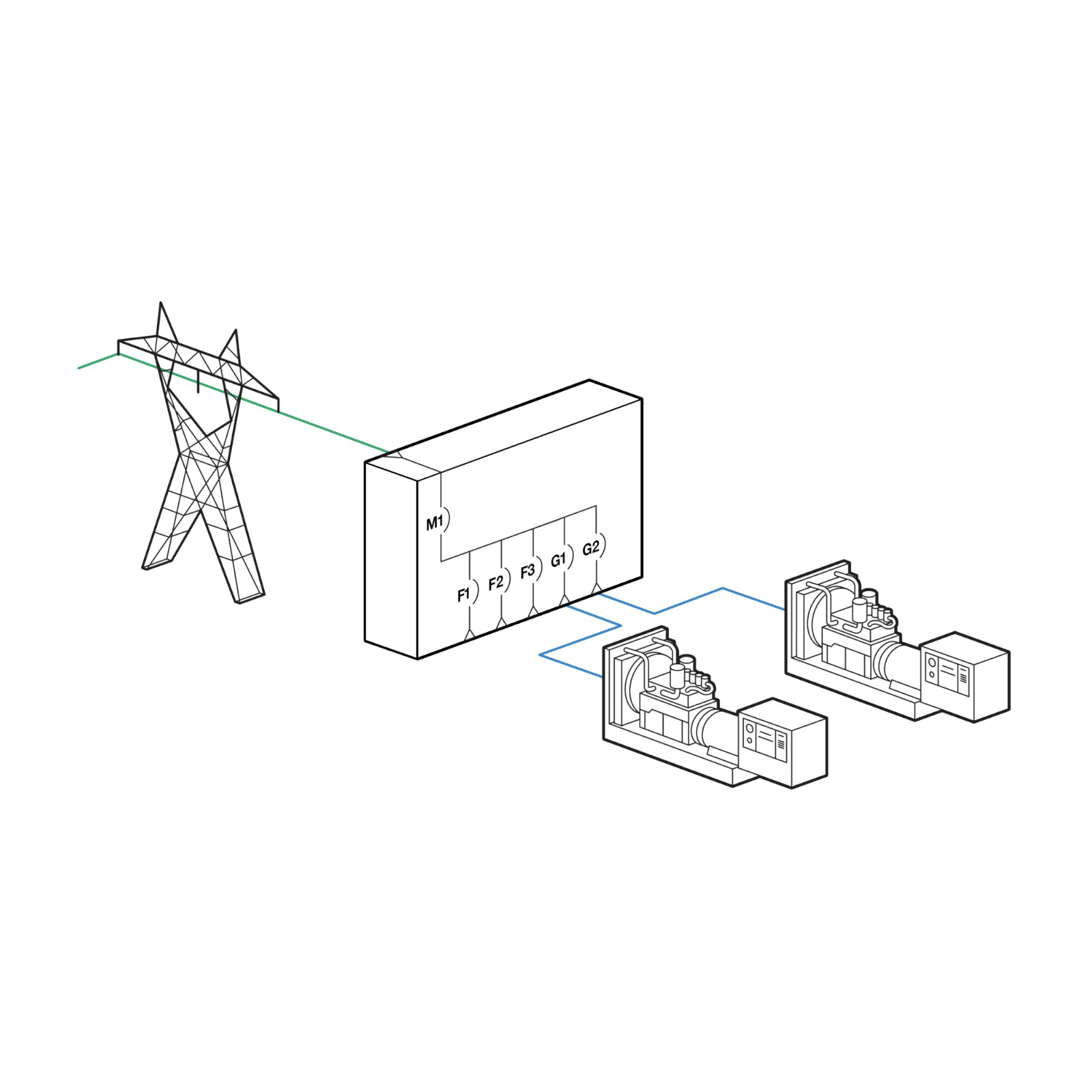

The other big part of the FHSU solution is the consultative efforts and guidance provided by Rehlko’s internal Power Solutions Team. The team played a significant role in updating the obsolete control equipment of the generator paralleling switchgear which incorporated new programmable logic controllers (PLCs) and user friendly human machine interface control (HMIs) modules.

The team not only recommended the product, but also verified system operation and published responses to failure. The new interface and control circuits make it easy for the operator to fine-tune system operation given changing economic (e.g., the cost of diesel-generated energy versus utility-generated energy) and operational factors. Ultimately, enhanced control leads to more efficient and effective energy use, in alignment with the school’s green initiatives.

Given the retrofit project occurred during the academic year, it would also be necessary to prevent any academic disruption. The Power Solutions Field Services Team and distributor worked directly with Keith Dreher and his team to ensure a smooth transition in terms of maintaining power while the new equipment was installed and tested.

The solution for Fort Hays State University includes:

The project includes Rehlko generator sets with APM603 controllers, a Rehlko Sound Level 2 enclosure, two integral sub-base 48-hour fuel tanks with 2,960-gallon capacity, and Rehlko PD-Series utility paralleling switchgear.

KD Series Generator

APM603 Controller

Single Utility - Multiple Generators Switchgear

Results

Fort Hays State University has a lot of experience with peak shaving, and it has saved over $3.6 million in energy costs over the last 18 years. The new Rehlko generators will be able to enhance the savings and will also offer reduced life cycle costs without the burden of stack testing. The sustainability trend will only continue, and equipment will need to become increasingly environmentally friendly. With all the equipment working in concert via the updated switchgear and APM603 generator set controllers, FHSU looks forward to expanding its decarbonization and other green initiatives.

Case Study

Education

Learn why this university in Kansas trusts in a Rehlko Power System.

Case Study

Education

Rehlko generators helped North Iowa Community College cut utility costs and boost energy independence with a solar-integrated microgrid system.

Case Study

Water Utility - Pump Station

Learn how one town upgraded quiet, reliable generators for water infrastructure. Discover solutions that simplify purchasing and ensure resilience.